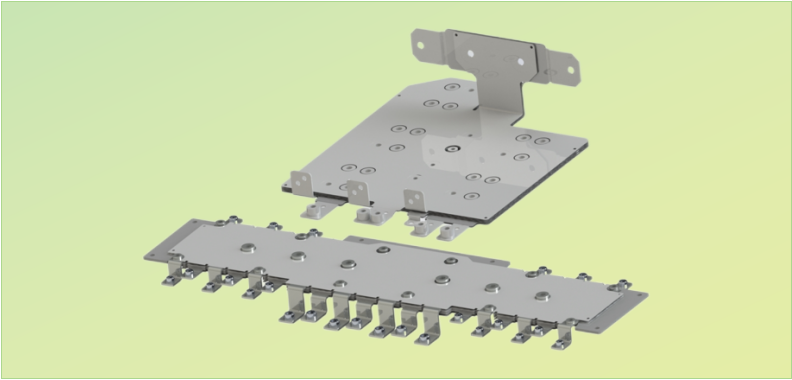

Laminated Busbar

Product Details

Advantage

- Low inductance, low impedance, high current carrying capacity

- Integrated error-proofing design, compact structure, saving internal space

- High reliability and long service life

- Customized design for easy assembly and on-site service

- Increase distributed capacitance

- It can realize the integration of components, such as integrated capacitors, inductors, resistors, etc

Performance Parameters

- Rated voltage: 400~6500V

- Rated current: 80~2000A

- Operating temperature: -40~105/130°C

- Heat and humidity resistance: 65°C/95%H

- Size: Customized design

- Conductor Material: Copper/Aluminum

- CTI Grade: II

FAQ

What are the core advantages of laminated busbars compared to traditional copper busbars?

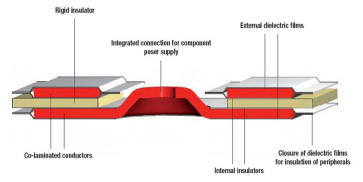

The core advantages focus on three aspects: electrical performance, space utilization, and reliability:

- In terms of electrical performance: The multi-layer structure shortens the loop distance, reduces parasitic inductance (usually down to below 10nH), minimizes switching losses, and is suitable for high-frequency power modules (such as SiC and GaN devices).

In terms of space utilization: Through the alternating lamination of insulation layers and conductor layers, the installation volume is significantly reduced (under the same current-carrying capacity, the volume can be reduced by 30%-50%), making it suitable for compact scenarios such as new energy vehicle battery packs and energy storage inverters.

In terms of reliability: The integrated structure reduces bolt connection points, lowering the risk of loosening under vibration. Additionally, the insulation layers (such as PP and PET) have a temperature resistance rating of over 120°C, adapting to harsh working conditions.

Related Products

Product Inquiry

If you are interested in our products, please contact us as soon as possible!