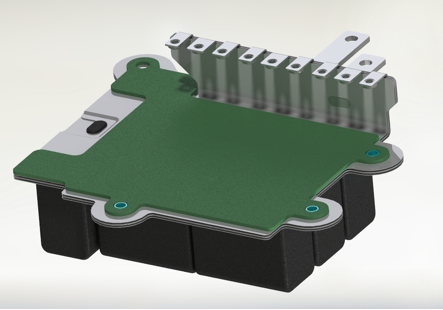

Integrated capacitor busbar

Product Details

Advantage

- Low inductance, capacitance busbar less than 10nH

- High current carrying capacity, the average current carrying density can be as high as 6A/mm2

- Light weight, 10%~20% lower than traditional capacitors

- High reliability and long service life All-in-one integrated design

Performance Parameters

- Rated voltage: 400~1100V

- Capacitance range: 80~1000μF

- Operating temperature: -40~105°C

- Heat and humidity resistance: 85°C/85%H

- Current carrying capacity: ~650A

- Size: Customized design

FAQ

What are the standards for salt spray testing and vibration testing of busbars? How to ensure compliance?

Relevant industry standards should be referenced based on application scenarios, with key requirements as follows:

Salt spray test: Automotive-grade busbars (such as CCS) must comply with ISO 9227. After 48h of neutral salt spray testing (5% NaCl solution, temperature 35°C), Then conduct the test.

What are the common quality defects in busbar production? How to avoid them?

High-frequency defects focus on insulation layers, conductor connections, and appearance. Corresponding solutions are as follows:

Insulation layer bubbles/delamination: Pre-dry the insulation material before pressing (PP pre-drying at 80°C for 2h), and control the pressure (1.5-2MPa) and heating rate (5°C/min) during pressing to prevent air from being trapped.

Conductor welding虚接 (virtual connection): Prioritize laser welding for copper busbars (power 2000-3000W, spot diameter 0.3mm). After welding, perform a tensile test (copper-copper welding tensile force ≥ 15N/mm²) and inspect internal fusion via X-ray.

Edge burrs/scratches: Use a deburring machine (rotating speed 3000r/min) to process edges after cutting. Clean the conductor surface with alcohol before attaching the insulation layer to avoid poor adhesion due to oil stains.

Failure in voltage resistance test: Ensure uniform insulation layer thickness (tolerance ≤ 0.05mm) and round edge treatment (radius ≥ 1mm) to avoid electric field concentration and breakdown.

Related Products

Product Inquiry

If you are interested in our products, please contact us as soon as possible!