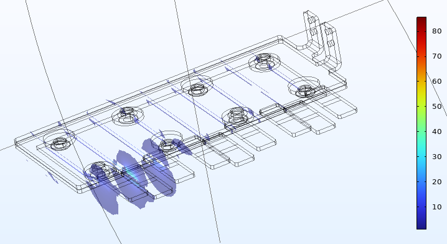

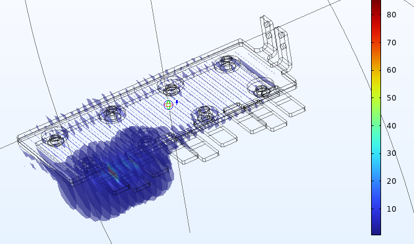

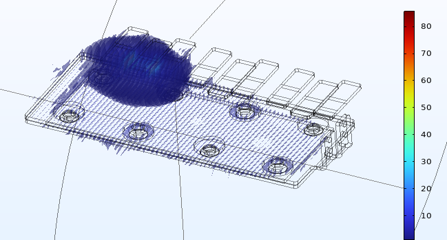

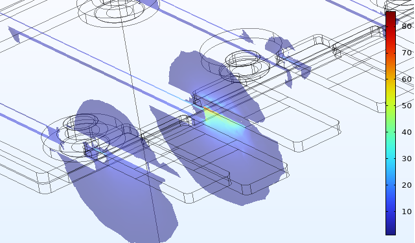

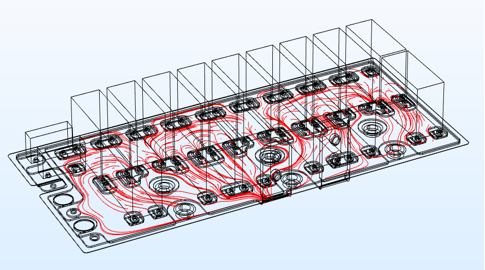

Simulation-inductance

Product Details

Advantage

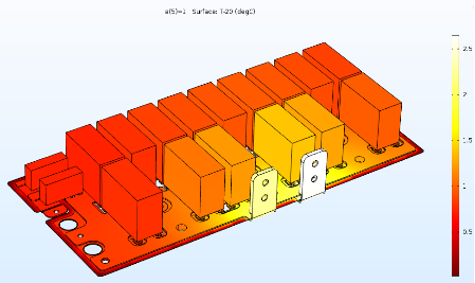

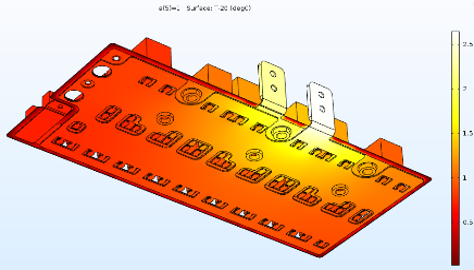

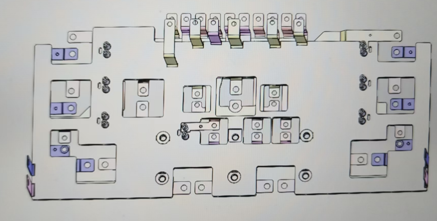

Self-heating simulation evaluates current density to determinate critical hot spots and to optimize conductor section with the right thickness vs width.

Achievement

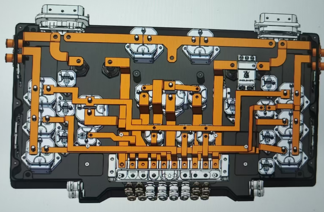

Based on the inverter busbar for hydrogen energy vehicles, we provide customers with a complete set of services from R&D, design, simulation to manufacturing, and integrate film capacitors into the busbar to increase reliability and lightweighting. We also integrated film capacitors into the busbar to increase reliability and light weight.

In the field of optical storage and charging application, we have successfully promoted the application of laminated busbar to a German company, and have completed the third round of design optimization and sample manufacturing. The project will be applied in the U.S. and European markets.

FAQ

What are the common types of electroplating for busbars?

Common Busbar Electroplating Types

- Tin Plating: High conductivity, good weldability, low cost (5-20μm thick); for industrial/low-voltage busbars.

- Nickel Plating: Corrosion/high-temp resistant, hard (3-20μm thick); for high-temp/wear-resistant busbars.

- Silver Plating: Ultra-high conductivity, low contact resistance (1-10μm thick); for high-frequency/high-current busbars.

- Gold Plating: Top corrosion resistance, stable contact (0.5-5μm thick); for aerospace/medical busbars (high cost).

- Others: Tin-lead (phased out, non-environmental), zinc (auxiliary anti-corrosion). Choose by scenario, process, cost.

Related Products

Product Inquiry

If you are interested in our products, please contact us as soon as possible!