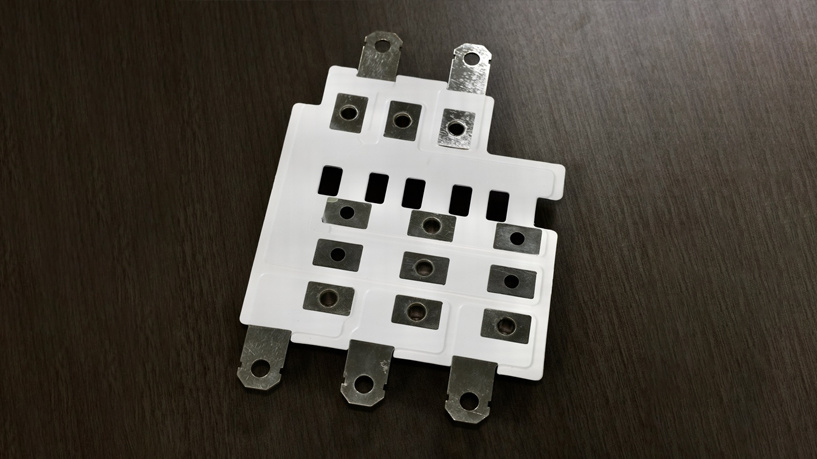

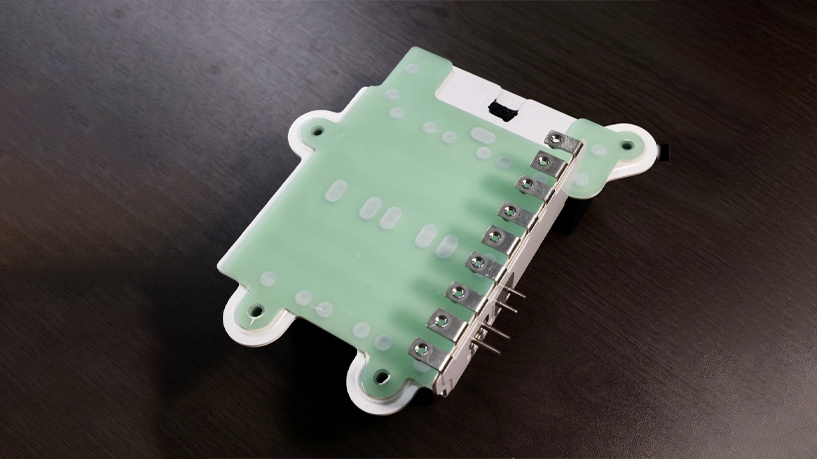

LATEST PRODUCTS

Solutions

To be a world-class material supplier and help customers win the global market

ABOUT US

A&J Link

Technology(Suzhou) Co.,Ltd

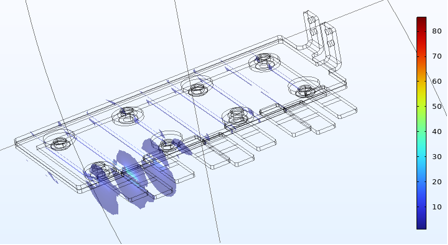

A&J Link Technology(Suzhou) Co., Ltd. traces its roots back to Suzhou Aierjie New Material Technology Co., Ltd., which was founded in 2017. Since its establishment, it has been dedicated to the research and development, design, production and manufacturing of PP, PC insulating sheets and busbars. With continuous technological investment and innovation, its products have been widely used in fields such as electronic appliances, automotive interiors and household products, and have gradually expanded to the three-electric system of new energy components. Adhering to a customer-centric approach, it has been actively providing solutions and establishing a rapid response mechanism, thus gaining market recognition.

Founded in

Registered Capital

Exporting country

Company staff

LATEST BLOGS

Polished Technical Report: Resistance Efficiency of Bolted Copper Busbar Connections

2026-01-02

2025-11-13

A&J Achieves ISO 14001 Certification, Strengthening Commitment to Sustainable Operations

2025-07-12

A&J Achieves Full Paperless Production via Macro-ERP Integration

2025-06-26